Manufacturer and Supplier

Suction Filter

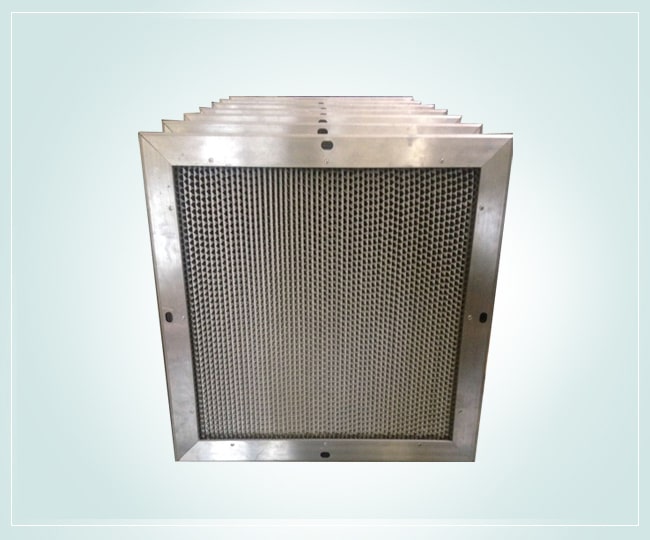

These are mainly installed within the tank before the suction pump and thus the name. These filters are mainly used to protect coarse contaminants from entering into the system, which have not been filtered elsewhere. These are wire mesh filters and thus can be used again after cleaning during the shutdown of the machines or systems. These come with standard sizes and standard micron rating, but we can always manufacture products of odd sizes for our customers with micron rating down to 5 microns.

Suction Filter

- Flow capacity ranges from 15 to 600 LPM.

- Cost efficient end caps made up of ABS material.

- M.O.C. of wire mesh can be SS 304 and SS 316 both.

- Working temperature range -20 to +100ºC.

- Micron rating 149 (standard) and can go down to 5 micron

Suction Filter Manufacturers and Suppliers in Ahmedabad, India

A suction filter, also known as a hydraulic suction strainer or suction screen, is a type of filter used in hydraulic systems to protect the hydraulic pump from ingesting debris and contaminants during the suction process. It is typically located at the inlet or suction line of the hydraulic pump.

The primary function of a suction filter is to prevent solid particles, such as dirt, metal chips, and debris, from entering the hydraulic pump, which can cause damage, wear, and reduced pump performance. It acts as the first line of defense in filtering the hydraulic fluid before it enters the system.

Suction filters are designed to capture larger particles and prevent them from reaching the pump. They are generally constructed with a mesh or perforated screen made of materials such as stainless steel, brass, or synthetic materials. The filter screen or mesh has a specific opening size that allows the hydraulic fluid to pass through while retaining larger contaminants.

Some key features and benefits of suction filters include:

Particle Filtration: Suction filters effectively capture and retain larger particles, preventing them from entering the hydraulic pump and other system components. This helps protect the pump from damage and extends its lifespan.

Pump Efficiency: By removing debris and contaminants, suction filters contribute to the efficient operation of the hydraulic pump. Cleaner hydraulic fluid allows the pump to perform optimally and maintain consistent flow rates.

Easy Installation and Maintenance: Suction filters are typically easy to install and remove for maintenance purposes. They are designed for quick access and cleaning, ensuring minimal downtime during filter maintenance.

Compatibility: Suction filters are compatible with various hydraulic fluids and are suitable for a wide range of hydraulic applications.

It's important to note that suction filters primarily focus on larger particles and are not designed for fine filtration. In systems where fine filtration is required, additional filters, such as pressure line filters or return line filters, may be used in conjunction with the suction filter to provide comprehensive filtration.

When selecting a suction filter, considerations include the required mesh or opening size, compatibility with the hydraulic fluid, flow rate and pressure requirements, and the specific application needs.

Suction filter is a type of filter used in hydraulic systems to protect the hydraulic pump from ingesting larger particles and contaminants. It captures debris before it enters the pump, contributing to pump efficiency and longevity. Suction filters are designed for easy installation, maintenance, and compatibility with hydraulic systems across various applications.