Manufacturer and Supplier

Pressure Line Filter

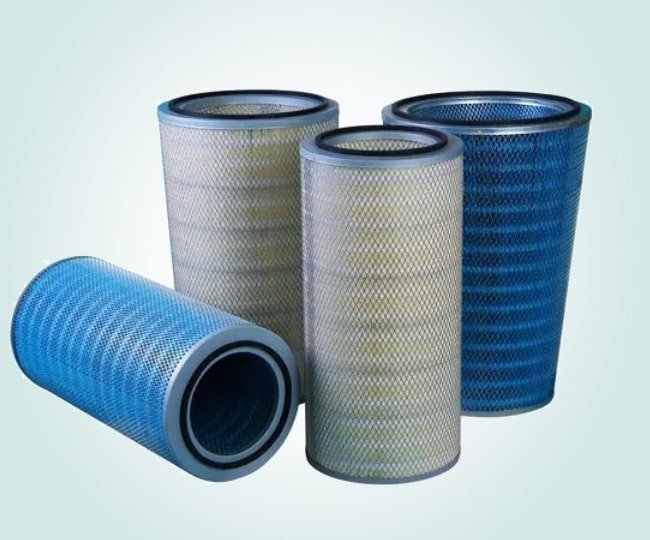

We are offering Pressure Line Filter that is designed to bear pressure up to the range of 210 bar or even more. In order to eliminate capitation problems and protect the valves from pump failures, we install them in between the pump and the control valves. The failure of these pumps can lead to loss up to millions of rupees.

Features

- Absolute filtration down to 3 micron

- High chemical resistance due to use of epoxy resin for impregnation and bonding

- High burst pressure resistance during cold start

- Superb adsorption of finest particles over a wide differential pressure range

- High contamination retention capacity

Pressure Line Filter Manufacturers and Suppliers in Ahmedabad, India

A pressure line filter, also known as a pressure filter or a high-pressure hydraulic filter, is a type of filter used in hydraulic systems to remove contaminants from the pressurized hydraulic fluid before it reaches hydraulic components. It is designed to ensure the cleanliness and proper functioning of the hydraulic fluid under high-pressure conditions.

Pressure line filters are typically installed in the hydraulic system's pressure line, which carries pressurized fluid from the hydraulic pump to various hydraulic components, such as valves, cylinders, and actuators. The primary function of a pressure line filter is to capture and remove particles, debris, and contaminants that may be present in the hydraulic fluid.

Pressure line filters are specifically designed to withstand the high-pressure conditions of hydraulic systems. They are constructed with durable materials and components capable of withstanding the pressure and flow rates associated with the hydraulic system.

These filters are available in various configurations, including inline filters, filter elements for use in filter housings, and spin-on filters. They are designed to meet specific flow rates, pressure ratings, and filtration requirements of the hydraulic system.

The key features and benefits of pressure line filters include:

Contaminant Removal: Pressure line filters effectively remove particles, debris, and contaminants from the pressurized hydraulic fluid, preventing them from entering and causing damage to sensitive hydraulic components.

Filtration Efficiency: Pressure line filters are available in different filtration ratings, typically measured in microns. They can be selected based on the required filtration level to meet the cleanliness requirements of the hydraulic system.

Protection of Hydraulic Components: By capturing and removing contaminants, pressure line filters help protect hydraulic pumps, valves, cylinders, and other components from premature wear, clogging, and potential failure. This improves the overall reliability and longevity of the hydraulic system.

Pressure Resistance: Pressure line filters are designed to withstand the high-pressure conditions commonly found in hydraulic systems, ensuring reliable operation without compromising filter integrity.

Extended Component Lifespan: The removal of contaminants by pressure line filters helps extend the lifespan of hydraulic components by minimizing wear and preventing damage. This leads to reduced maintenance and replacement costs.

Proper selection, installation, and maintenance of pressure line filters are crucial to ensuring their optimal performance in hydraulic systems. Factors to consider when selecting a pressure line filter include the flow rate, pressure rating, filtration efficiency, compatibility with the hydraulic fluid, and system specifications.

Pressure line filter is a hydraulic filter used to remove contaminants from pressurized hydraulic fluid before it reaches hydraulic components. It plays a critical role in protecting sensitive components, maintaining system cleanliness, and ensuring reliable operation in high-pressure hydraulic systems. Pressure line filters contribute to improved system performance, reduced maintenance, and increased component lifespan.