Manufacturer and Supplier

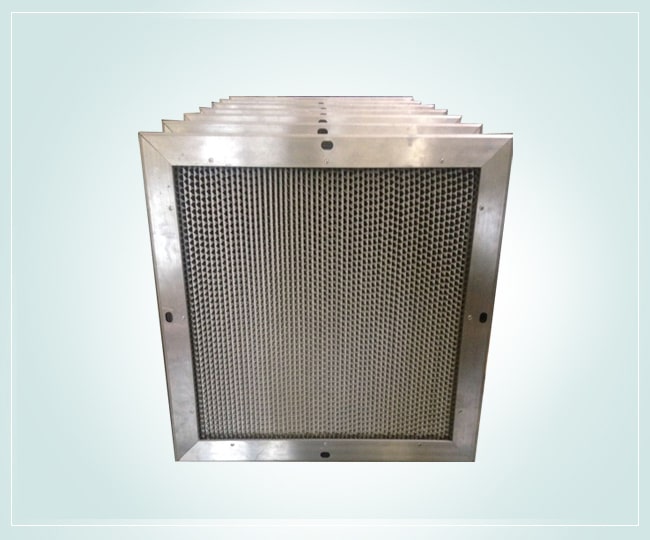

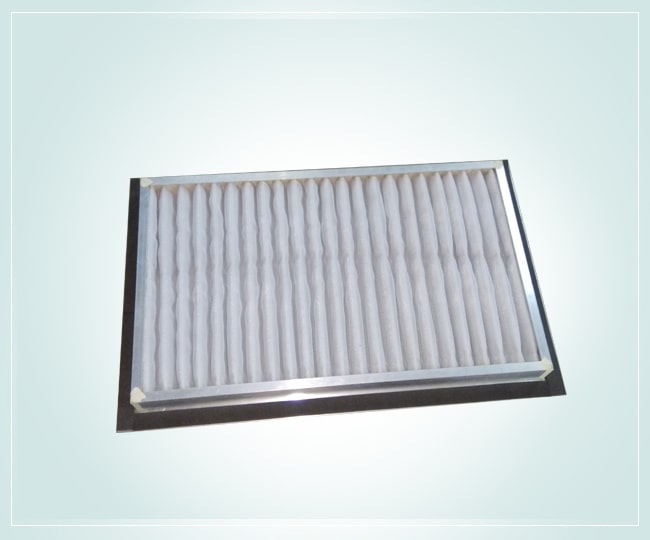

Return Line Filter

These Return Line Filter unlike In line Filters bear low pressure up to a range to 25-30 bar and thus is installed on the return line between the reservoir and the pump intake. Since these filters are in return line, these are fitted with a by-pass valve, thus when the filter get chocked, the relief valve opens up and the flow to the reservoir is uninterrupted.

Features

- Exemplary beta stability over a wide differential pressure range

- High contamination retention capacity

- High chemical resistance

- High burst pressure resistance during cold start

- Water and water traces in the fluid do not reduce filtration effect

- Absolute micron rating down to 3 micron

Return Line Filter Manufacturers and Suppliers in Ahmedabad, India

A return line filter, also known as a return filter or a return line hydraulic filter, is a type of filter used in hydraulic systems to clean the hydraulic fluid before it is returned to the reservoir or hydraulic tank. It is an essential component in hydraulic systems to maintain the cleanliness and proper functioning of the hydraulic fluid.

The return line filter is typically located in the return line of the hydraulic system, which carries the hydraulic fluid from the hydraulic actuator or component back to the reservoir. The primary function of the return line filter is to capture and remove contaminants, such as particles, debris, and wear metals, that may have accumulated in the hydraulic fluid during system operation.

Return line filters are available in various configurations, including spin-on filters, inline filters, and filter elements that fit into filter housings. They are designed to meet specific flow rates, pressure ratings, and filtration requirements of the hydraulic system.

The key features and benefits of return line filters include:

Contaminant Removal: Return line filters effectively remove particles, debris, and other contaminants from the hydraulic fluid, preventing them from circulating further in the system and causing damage to hydraulic components.

Filtration Efficiency: Return line filters are available in different filtration ratings, typically measured in microns. They can be selected based on the required filtration level to meet the cleanliness requirements of the hydraulic system.

Protection of Hydraulic Components: By capturing and removing contaminants, return line filters help protect hydraulic pumps, valves, cylinders, and other components from premature wear and potential failure. This improves the overall reliability and longevity of the hydraulic system.

Extended Fluid Life: The removal of contaminants by return line filters helps maintain the cleanliness and quality of the hydraulic fluid, which extends its useful life. This reduces the frequency of fluid replacement and lowers maintenance costs.

Ease of Maintenance: Return line filters are designed for easy installation, replacement, and maintenance. They are typically equipped with bypass valves or indicators to monitor filter condition and facilitate timely maintenance.

Proper selection, installation, and maintenance of return line filters are essential to ensure their optimal performance in hydraulic systems. Factors to consider when selecting a return line filter include the flow rate, pressure rating, filtration efficiency, compatibility with the hydraulic fluid, and system specifications.

In summary, a return line filter is a hydraulic filter used to clean the hydraulic fluid as it returns to the reservoir or hydraulic tank. It removes contaminants to protect hydraulic components and maintain the cleanliness and functionality of the hydraulic system. Return line filters contribute to improved system performance, reduced maintenance, and increased component lifespan.