Manufacturer and Supplier

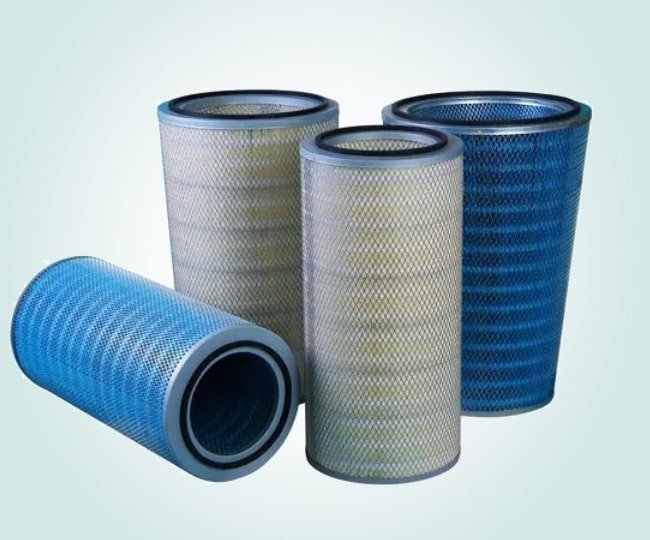

Pleated Dust Collection Bags

Our firm offers a complete range of Pleated Dust Collection Bag that is commonly used in the field of dust collection system. These bags are made from 100 per cent Spun Bonded polyester media with various coatings on it. Then this spun bonded media are pleated in different pleated depths & heights to accommodate filtration area according to the demand. It offers surface filtration which makes pleated bags to offer high throughput & lower pressure drop across the filter compared to any conventional tube type filter bags. Pleated configuration offers almost 3 to 4 times higher filtration area in comparison to conventional bags.

Construction

- Pleated spun bonded polyester filter media is basically placed in a cylindrical configuration with support cage of Galvanized / stainless steel / Polypropylene & encapsulated with EPDM / Natural rubber / Polyurethane or metal end caps to form a pleated dust collection bag

- Longitudinal joints of pleated bags are ultrasonically fused for leak proof & very stable design

- The end caps are configured to mount as clean side or dirt side fitments

- In case of metal caps these bags are supported with soft sponge rubber or snap band cuff sealing to ensure positive sealing of filter while fitments

Pleated Dust collection Bags Manufacturers and Suppliers in Ahmedabad, India

Pleated dust collection bags, also known as pleated filter bags or cartridge filters, are specialized filters used in dust collection systems to capture and remove dust and particulate matter from industrial processes. They are commonly employed in industries such as woodworking, metalworking, mining, pharmaceuticals, and many others where dust or fine particles are generated.

Unlike traditional flat or cylindrical dust collection bags, pleated dust collection bags feature a pleated or folded design. The pleats increase the surface area of the filter media, allowing for greater filtration efficiency and a higher dust-holding capacity.

The pleated filter media is typically made of materials such as polyester, polypropylene, or other synthetic fibers. The filter media is pleated and held together by a rigid frame or support structure. The pleated design provides an extended surface area for dust collection, which improves the overall performance and lifespan of the filter.

Some key features and benefits of pleated dust collection bags include:

Increased Filtration Surface Area: The pleated design significantly increases the surface area available for dust collection compared to traditional flat bags. This allows for improved filtration efficiency and longer service life before filter replacement or cleaning is required.

Enhanced Dust Holding Capacity: The pleated design provides a larger dust-holding capacity, enabling the filter to collect and retain a greater amount of dust particles without compromising airflow and filter performance.

Lower Airflow Resistance: Pleated dust collection bags typically have a lower pressure drop or airflow resistance compared to traditional flat bags. This results in improved system airflow and energy efficiency, reducing the load on dust collection equipment.

Compact Size: Pleated filter bags are generally more compact in size compared to traditional bags. This allows for easier installation, replacement, and maintenance in dust collection systems.

Versatility: Pleated dust collection bags are suitable for a wide range of dust collection applications. They can be used in various types of dust collectors, such as pulse-jet collectors, reverse air collectors, and cartridge collectors.

When selecting pleated dust collection bags, factors to consider include the filtration efficiency, the dust particle size and type, the specific application requirements, and compatibility with the dust collection system. It's important to follow manufacturer recommendations for filter replacement schedules and maintenance to ensure optimal dust collection performance.

Pleated dust collection bags are specialized filters used in dust collection systems to capture and remove dust and particulate matter. Their pleated design increases filtration surface area, enhances dust-holding capacity, reduces airflow resistance, and provides compact size for easy installation and maintenance. These bags offer improved filtration efficiency and longer service life, contributing to effective dust control in industrial processes.