Manufacturer and Supplier

Gas Turbine Air Intake Filter

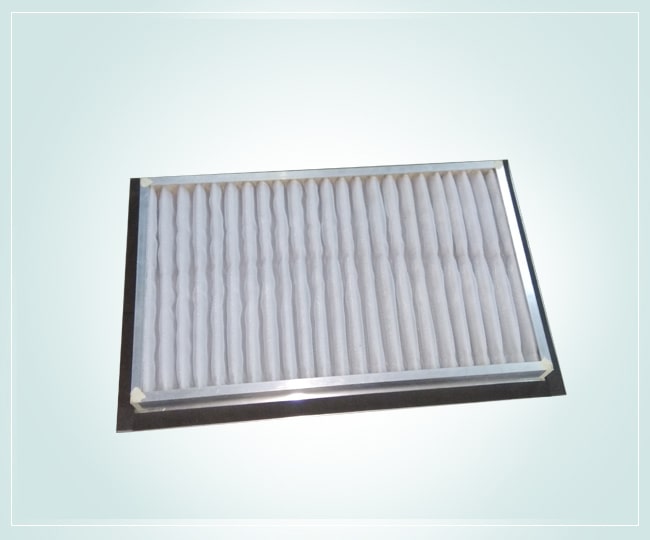

Our domain expertise has enabled us in offering highly effective and efficient range of Gas Turbine Air Intake Filter, which is made of mixture of polyester & cellulose and sometime 100% polyester media. An ideal solution for air intake applications, these filters are capable of removing dust and other contaminants even in the most polluted environments. Featuring attributes like high filtration efficiency, very fine retention level, easy clean ability and dimensional ability, these filters are highly demanded amidst clients in varied industries.

Advantages

- Easy to clean

- High flow efficiency

- High Air to cloth ratio

- Large spacing

Technical Specifications

- Filter media

- Mixture of Cellulose & Polyester Media

- 100 % spun bonded polyester

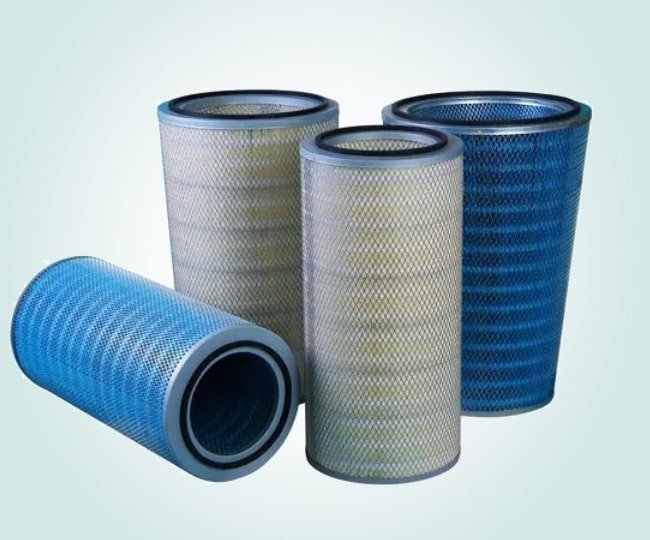

- Configuration

- Cylindrical

- Conical

Applications

- All types of air intake applications

Gas Turbine Air Intake Filter Manufacturers and Suppliers in Ahmedabad, India

A gas turbine air intake filter, also known as a turbine inlet air filter or GT air filter, is a specialized air filter used to protect gas turbines from ingesting airborne contaminants during operation. Gas turbines are widely used in power generation, oil and gas, and other industrial applications, and the air intake filter plays a crucial role in maintaining their performance and reliability.

The primary function of a gas turbine air intake filter is to prevent the entry of particles and debris, such as dust, dirt, sand, insects, and other airborne contaminants, into the gas turbine's compressor section. These contaminants can cause erosion, fouling, corrosion, and reduced efficiency of the turbine components if they are not adequately filtered.

Gas turbine air intake filters are designed to meet specific filtration efficiency requirements while allowing for sufficient airflow to meet the turbine's operational needs. They are typically high-efficiency filters that can remove a wide range of particle sizes to protect the turbine from damage.

These filters are usually large and installed at the air intake system of the gas turbine, where they capture airborne contaminants before they enter the compressor. The filter housing or frame is designed to withstand the environmental conditions, such as high temperatures, humidity, and corrosive gases, that may be present in the turbine environment.

Some key features and characteristics of gas turbine air intake filters include:

High Filtration Efficiency: Gas turbine air intake filters are designed to provide high filtration efficiency, often exceeding 99% for certain particle sizes. This ensures the removal of fine particles that could potentially damage turbine components.

Low Pressure Drop: Gas turbine air intake filters are engineered to have a low resistance to airflow, minimizing the pressure drop across the filter. This allows for efficient turbine operation with optimal power output and reduced energy consumption.

Durability and Long Service Life: Gas turbine air intake filters are built to withstand demanding environments and maintain their performance over an extended period. They are designed to handle high airflow volumes, temperature variations, and potential exposure to moisture and corrosive gases.

Maintenance and Monitoring: Regular maintenance and monitoring of gas turbine air intake filters are essential to ensure optimal performance. Filter replacement schedules and differential pressure monitoring are commonly employed to determine the appropriate timing for filter changeouts.

Proper selection, installation, and maintenance of gas turbine air intake filters are critical to protect the turbine from damage and maintain its efficiency. The selection process considers factors such as the required filtration efficiency, airflow capacity, environmental conditions, and specific turbine manufacturer recommendations.

In summary, gas turbine air intake filters are specialized filters designed to protect gas turbines from ingesting airborne contaminants. They provide high filtration efficiency, low pressure drop, and durability to maintain the performance and reliability of gas turbine systems.